January 12, 2026 at 12:00 AM

In this article, we answer common questions about volatile corrosion inhibitors (VCI) technology — including its benefits, uses, formulations and advantages plus show how they integrate with preservation management, rig stacking, mothballing, and dehumidification solutions.

Corrosion is one of the biggest challenges industrial companies face, from spare parts in storage to offshore rig equipment and long-term plant lay-up. Selecting the right preservation method can protect assets, reduce maintenance costs, and extend equipment lifespan. Whether you are protecting pumps, valves, heat exchangers, structural steel, or rotating equipment, this frequently asked question list draws on real-world applications and case histories to guide your corrosion prevention strategy.

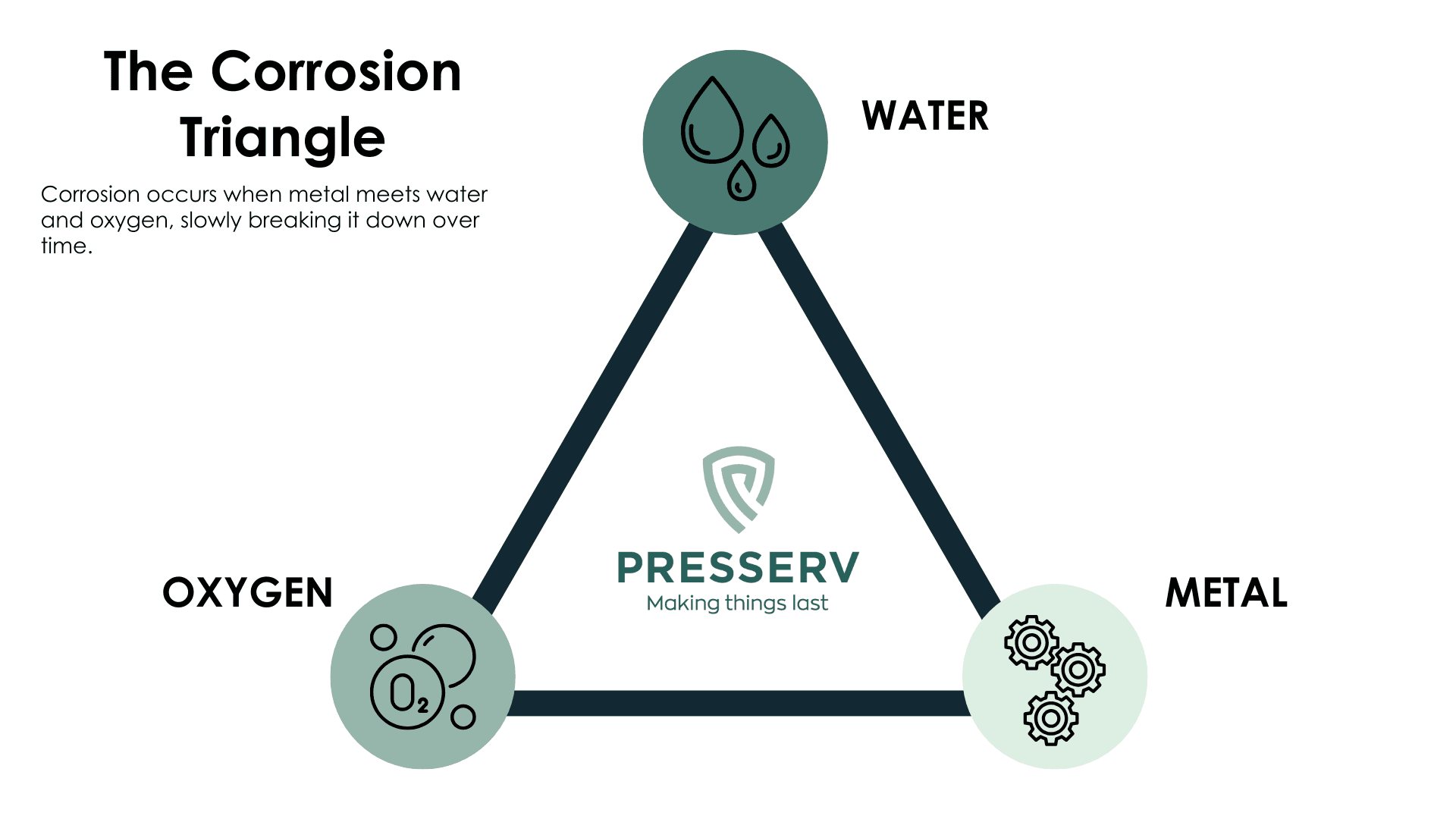

Q: What causes corrosion?

Corrosion is caused by a chemical or electrochemical reaction between a material—usually a metal—and its environment, leading to gradual deterioration. For corrosion to occur, three key components are generally required:

Metal – The material that will undergo corrosion.

Electrolyte – A conductive medium that allows ion movement (like water, especially with dissolved salts or acids).

Oxygen or another oxidizing agent – Needed to accept electrons from the metal and drive the reaction.

Q: What are ferrous and non-ferrous metals?

Ferrous metals contain iron (steel, cast iron) and form red rust. Non-ferrous metals (aluminum, copper, brass, zinc) corrode via different mechanisms. Multi-metal VCI formulations are used when both types of metal are present.

Q: What are VCIs? What is VCI technology?

VCIs, otherwise known as volatile corrosion inhibitors, are used to protect assets from corrosion. VCI technology protects ferrous and non-ferrous metals from corrosion during usage, storage and transit.

Q: What are VpCIs®?

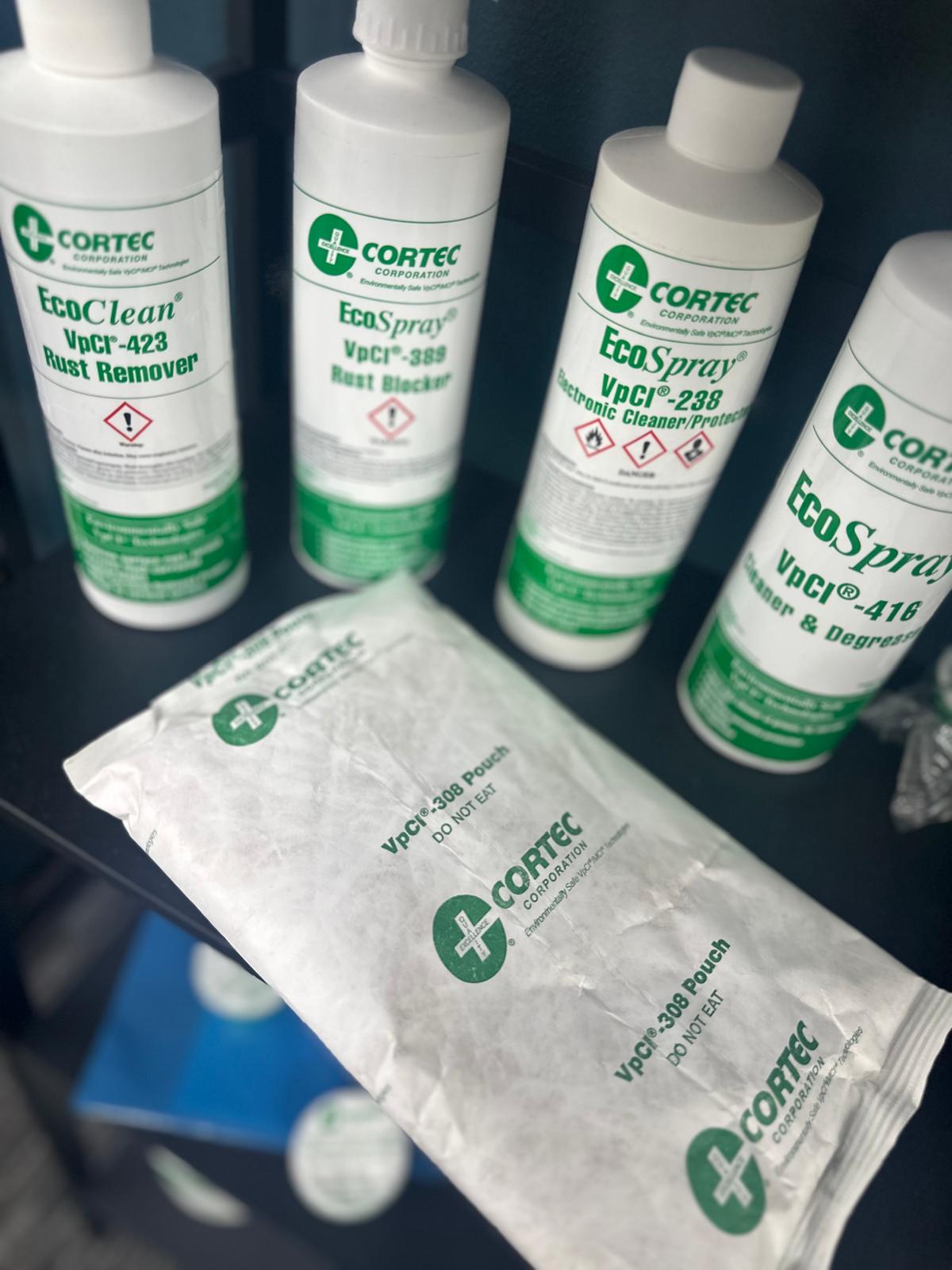

Vapor phase Corrosion Inhibitors, or VpCIs®, are Cortec Corporation’s brand of trademarked VCI technology, delivering both vapor diffusion and contact protection. VpCI® technology is widely used in regional preservation procedures and validated in published global case histories.

VCIs under the Cortec Corporation VpCI® brand name are generally safer to handle and less hazardous than other VCIs such as DICHAN (one of the first, highly toxic VCIs on the market) or those that rely heavily on nitrites. Many Cortec Corporation products are recyclable or compostable and typically have a lower environmental impact than harsher chemicals.

Q: How does VCI work?

VCI molecules vaporize, diffuse through enclosed void space (crates, containers, tanks, cabinets), adsorb onto metal, and disrupt electrochemical corrosion reactions — preventing different types of corrosion.

Q: Which industries benefit most from VCI technologies?

VCIs offer versatile protection across metals and components, minimal disruption to day-to-day operations or start-up, and long-term storage solutions for greenfield and brownfield assets. Thus, VCIs are beneficial to many industries including oil & gas, nuclear, mining, refineries, petrochemicals, paper manufacturing, food production and utilities plus industries with particularly corrosive environments.

Q: Are VCI solutions safe for operators and the environment?

Most VpCI® products offer solvent-free and nitrite-free options, supporting safer operator handling and environmentally responsible corrosion management.

Q: How long can industrial assets and equipment be preserved using VCIs?

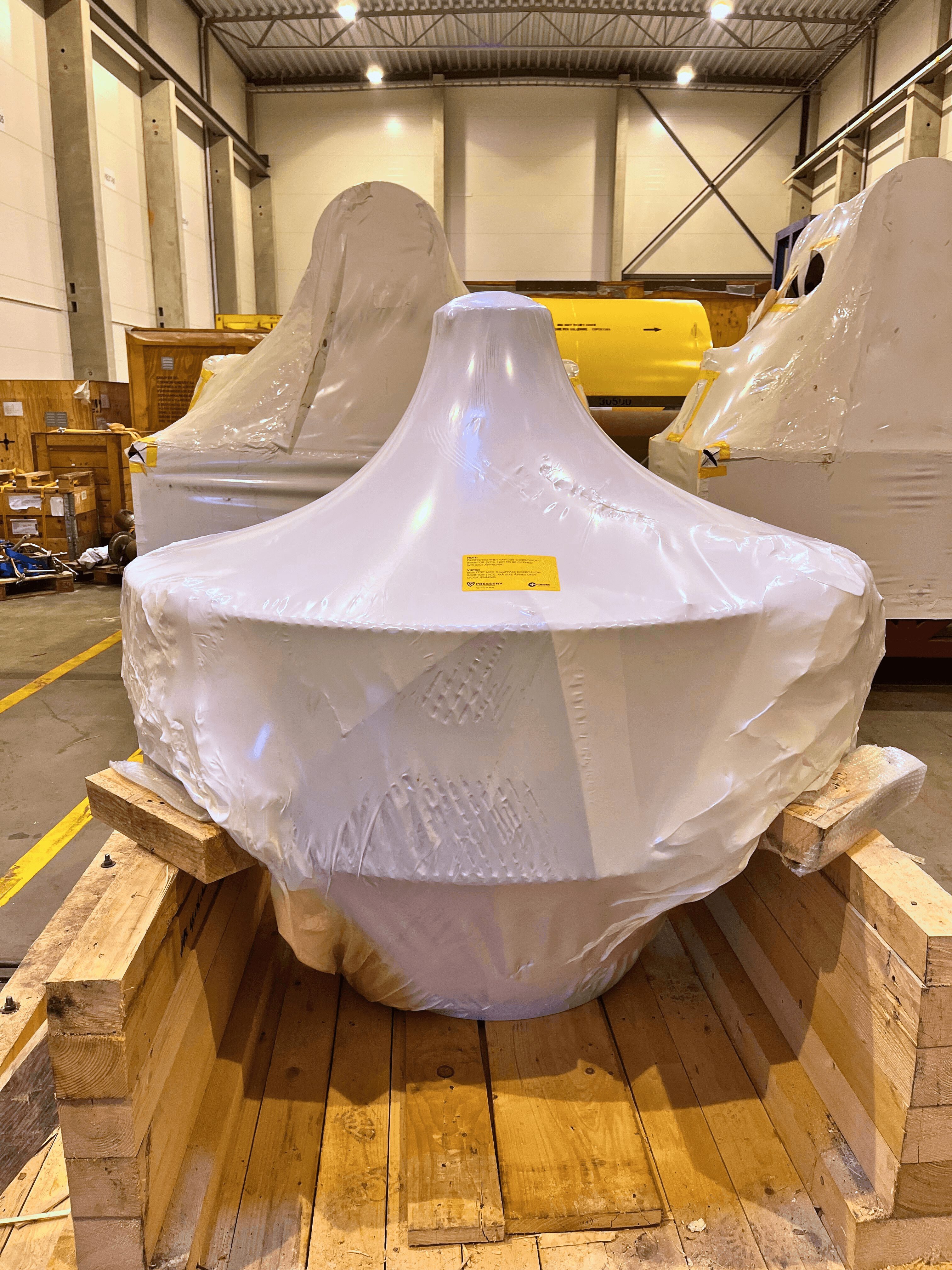

In most cases, industrial assets and equipment can be protected for up to 24 months when treated correctly. Some industrial assets and equipment can be protected for up to 5 years. However, protection lasts only when sufficient vapor concentration is maintained. Larger enclosure volumes require correct sizing or additional emitters, especially for offshore export or pipeline preservation.

For longer term storage and more complex preservation VCIs are often paired with desiccants and high-performance adsorption-type dehumidifiers for industrial and commercial applications or other products.

Q: Is airtight packaging required for VCIs to work?

Not strictly, but airtight sealing enhances vapor retention. Cortec VpCI® films and bags maintain molecular protection even in partially ventilated enclosures, but proper sealing maximizes shelf life and efficiency, especially for stored pumps, valves, and structural steel.

Q: Does Cortec Corporation produce military grade products?

Yes. Cortec Corporation produces products which meet multiple military and defense specifications and have been used in approved long-term storage and asset protection projects for governmental clients.

You can read more about a few specific products used by global military personnel here:

VpCI®-126 HP UV Shrink Film - combines high strength resins with ultraviolet light stabilizers (UV) and Vapor phase Corrosion Inhibitor (VpCI®) Technology.

MilCorr® VpCI® Shrink Film - ideal for industrial packaging and long-term storage, this shrink film safeguards components from rust, corrosion, and environmental damage.

VpCI®-101 Device - provides corrosion protection for components and parts enclosed in non-ventilated control boxes, cabinets, or toolboxes.

VpCI®-111 Emitter – similar to VpCI®-101 devices, but designed for larger spaces.

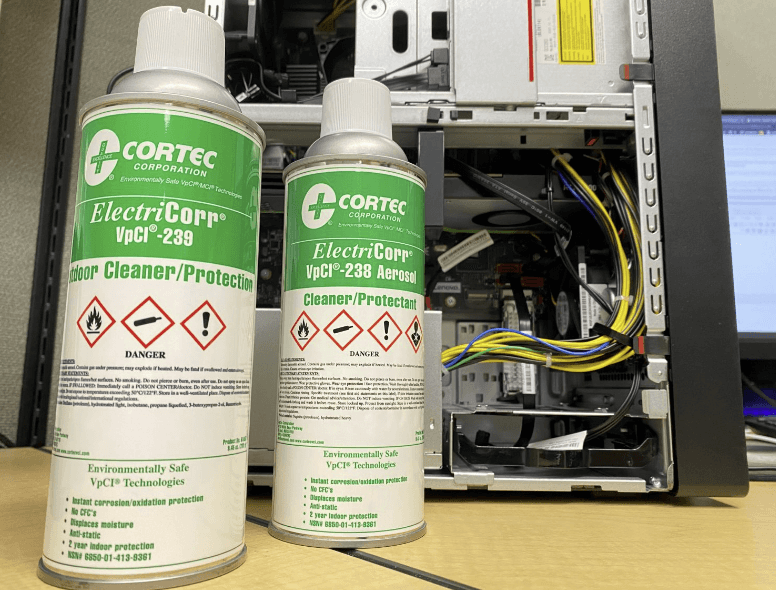

ElectriCorr® VpCI®-238 - an electronic cleaner containing Vapor phase Corrosion Inhibitors (VpCI®), can be safely applied to protect circuits or relays without causing any changes in conductivity.

VpCI®-239 Multi-Metal Cleaner/Protector - can be safely used with most plastics, elastomers, and other non-metallics, free of CFCs and 1,1,1-Trichlorethane. Provides instant corrosion protection.

Q: What are the three most important factors within a manufacturing process that influence corrosion?

1) Surface cleanliness and contamination, 2) exposure to moisture or humidity and 3) temperature fluctuations. Controlling these improves VpCI® effectiveness and therefore corrosion protection.

Q: Are Cortec VpCI® products recyclable or compostable?

Many Cortec VpCI® papers and films are recyclable or compostable depending on local facilities.

VpCI®-148 Paper – a recyclable, grease-resistant, corrosion inhibiting packaging material.

EcoShield® VpCI®-144 – a premium recyclable and repulpable moisture barrier corrosion inhibiting paper.

EcoShrink™ Compostable Film - certified industrially compostable and designed for use in standard heat shrinking applications.

EcoWrap® Stretch Film – the world’s first compostable industrial strength machine grade stretch film.

Q: Do spare parts have to be dry before they are wrapped and stored with VCI products?

Yes. Moisture can overwhelm inhibitors, negating preservation efforts.

Q: Will oil, lubricants, or transmission fluids affect the performance of VpCI® products?

Hydrocarbon oils generally do not neutralize VpCI® vapors, though heavy coverage can reduce exposed surface area. Proper formulation selection ensures reliable protection.

Q: How can I purchase VCI products?

If you are interested in learning more about how VCIs can help you meet your corrosion prevention needs, contact us for more information.