January 9, 2026 at 12:00 AM

Learn how VCI (Vapor Corrosion Inhibitor) technologies protect industrial assets from corrosion.

Corrosion is one of the costliest challenges facing industrial operations worldwide. According to NACE International, corrosion costs the global economy over $2.5 trillion annually, impacting infrastructure, equipment reliability, and operational safety. For industrial companies, unplanned downtime, equipment replacement, and asset degradation can significantly affect productivity and profitability.

Proactive corrosion protection strategies are essential to preserving asset integrity, ensuring reliability, and extending equipment lifespan. One of the most effective solutions available today is vapor corrosion inhibitor (VCI) technology, which offers versatile, safe, and efficient protection for assets in storage and transit, or during operational downtime.

This article explores various types of VCI technologies, their industrial applications, and how companies can select the right solution for their assets and equipment.

What is VCI Technology and How Does it Protect Industrial Assets?

Vapor corrosion inhibitor (VCI) technology protects metals by releasing corrosion-inhibiting molecules into the air inside enclosed spaces. These molecules form an invisible protective layer on metal surfaces, preventing oxidation and rust even in hard-to-reach areas.

Cortec Corporation’s branded VpCIs are generally safer than alternatives like DICHAN and are designed to reduce operator exposure plus environmental hazards without compromising effectiveness.

VCIs can be applied to a wide range of industrial assets—including pipelines, storage tanks, rotating machinery, and structural steel—and offer several advantages over traditional coatings, oils, or greases:

Non-contact protection for complex geometries.

Long-lasting performance in storage and transit conditions.

Compatibility with mechanical and electrical equipment.

By integrating VCIs into preservation strategies, industrial companies can reduce corrosion-related downtime and maintenance costs while improving asset reliability.

Types of VCI Technologies and Their Industrial Applications

VCI Films and Bags

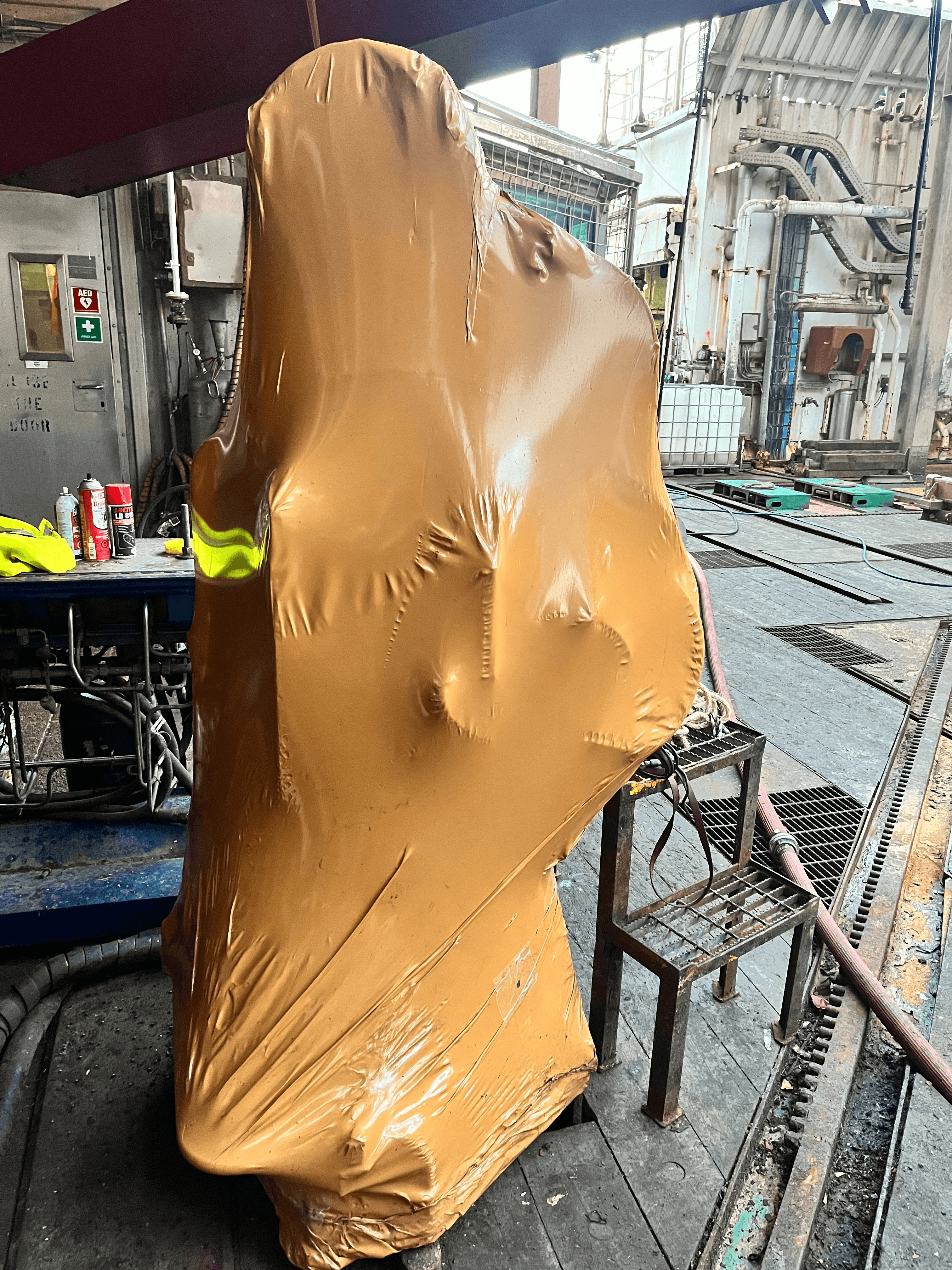

Plastic sheeting/films and bags come in many sizes and formats—from small top-seal bags that protect nuts and bolts, to 30 foot (9.1 m) wide heavy-duty sheeting for storing giant industrial equipment both in- and outdoors.

Applications include corrosion-free transport of goods and spare part preservation as well as several others.

VCI Inserts including Emitters, Sachets, Pouches and Impregnated Foam

Emitters, sachets, pouches, and impregnated foam inserts release corrosion inhibitors over time.

Provides continuous protection without direct operator application.

Reduce the need for applying hazardous and cumbersome rust preventatives.

Ideal for enclosed spaces, pipelines, vessels, and tanks. Also ideal for electrical junction boxes, control cabinets and instrument housings.

VCI Rust Removers, Cleaners and Desalination Products

Heavy duty cleaners, degreasers and primers protect from flash rust.

Desalination products remove salt contamination as it is a major corrosion accelerator.

Applications include plant lay-up, rig stacking, metalworking and in process industries.

VCI Solutions for Electrical and Instrumentation

Superior shields for electronics and instruments, especially in aggressive environments including industrial, marine, and tropical climates.

Special formulations offering instant corrosion protection without altering conductivity.

Products include films, bags, inserts/emitters, sprays, wipes and more.

VCI technologies also come in powders, oil additives, diesel additives and temporary coatings as well as other product formats.

How to Choose the Right VCI Technology for Your Industrial Assets

Selecting the correct VCI solution depends on:

Equipment type (rotating, static, electrical)

Storage environment (humidity, temperature, confined spaces)

Duration of storage (short-term vs long-term)

Risk factors (MIC, offshore conditions, corrosive environments)

VCI technologies provide industrial companies with reliable, safe, and efficient protection against corrosion and extend asset lifespan, thereby reducing unplanned downtime and ensuring operational reliability.

With decades of experience in asset preservation, we have helped industrial clients implement customized VCI corrosion mitigation strategies to protect critical assets across a variety of industries, including energy including oil and gas, renewables, nuclear and others; petrochemicals, mining, and logistics. Head to our case history page to read more detailed information about how we've helped our clients make things last.

For more information about our tailored solutions using VCIs for asset protection, contact us at https://www.presserv.com/contact.